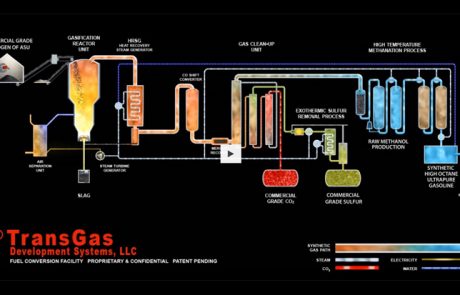

The Process – Turning Coal into Gas – Using Proven Technology

The coal-to-gasoline & coal-to-nitrogenous fertilizer processes

TransGas develops projects that use well-proven clean coal gasification technology, chemical transformation of coal into nitrogenous fertilizer, liquid fuels and industrial gases. Our projects do not use traditional combustion or coal burning. We employ a 100-year old German technology, with a lineage of over 500 gasifiers worldwide.

The most recent coal gasification projects by our partners were built in countries renowned by highest standards of environmental protection and safety, such as: France (2012) Sweden, Germany and the Netherlands (2011); and South Korea and the USA (2009)

The technology is so clean that TransGas projects in the United States have been the only coal to chemical projects to be fully permitted and receive the status of minor source of emissions per the US Environmental Agency – EPA regulations.

Clean Coal to Gasoline Process (CCTG)

The TransGas reference plant design transforms coal and water into gasoline and liquefied petroleum gas (LPG) using proven technologies in a unique combination that meets stringent US Clean Air requirements.

This video walks you through the science behind the TransGas technology system.

- Coal is received and ground to powder like consistency in enclosed structures that minimalize fugitive dust.

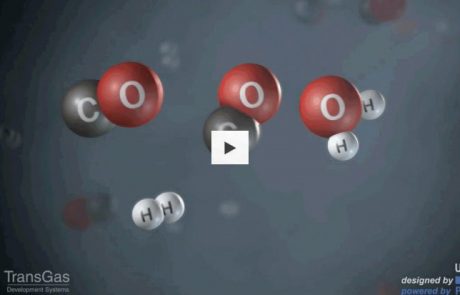

- Coal powder is injected into a high pressure vessel with carefully controlled portions of pure oxygen and steam. A chemical reaction called gasification occurs that produces a gas composed of carbon monoxide and hydrogen with trace amounts of carbon dioxide, hydrogen sulfide and smaller amounts of other gases. This gas mixture is referred to as raw syngas.

- The raw syngas is then passed through a series of processes where the trace gases are removed and converted into marketable products or solid materials that can be transported and used in other processes.

- Clean syngas is now ready for conversion to liquids. The first step is passing the syngas over a catalyst that separates the carbon monoxide into individual carbon and oxygen atoms that are then recombined with hydrogen molecules to form methanol.

- Methanol is not only a product unto itself and the basis for gasoline; but it is also used in the removal of carbon dioxide from the raw syngas. The TransGas system, unlike other fossil fuel processes, effectively captures its carbon dioxide and purifies it to near food grade quality ready for other uses.

- A unique component of the TranGas system is its ability to store methanol as an intermediate product. This allows a TransGas plant to achieve an availability percentage much higher than any other solid to liquid technology. TransGas can produce gasoline from stored methanol that means routine maintenance that interrupts production on other’s plants does not affect TransGas.

- Upon leaving this section of the TransGas system the gasoline is ready for use in the traditional distribution system. With only minor variation in standard additives it can be made compatible with any of the brands of gasoline on the market today.

The fact that clean syngas converted directly to liquid products without addition refinery operations separates the TransGas system from that of those based upon Fischer-Tropsch synthesis. This not only reduces the cost of construction and operations, it dramatically eliminates the creation of toxic air pollution associated with the refinery processes that are part of those other plants.

Clean Coal to Nitrogenous Fertilizers Process

TransGas also employs the well-proven clean coal gasification to convert coal into ammonia and then urea, the main component of nitrogenous fertilizers. The TransGas’ technology partners have already designed, built and put into successful operation 135 fertilizer plants worldwide.

Fertilizers

TransGas develops projects that employ clean coal gasification technology to convert coal into high valuable nitrogenous fertilizers, such as urea and UAN.

Why nitrogenous fertilizers?

Nitrogen is the building block of chlorophyll, the catalyst of the photosynthesis process. Plants need nitrogen to be green, have enough foliage – to survive.

Most of the available farmland lacks, however, enough nitrogen nutrients to be commercially productive. Actually, 70 per cent of the world’s farmland requires the addition of nitrogen-based fertilizer to become fertile and produce grains and food.

Without nitrogen increasing soil productivity, the world would be utilizing twice more farmland to produce the same quantities of food of today – the equivalent of 25 per cent of all forests on Earth.

As the world’s population is expected to reach 8,5 billion people by 2030, the United Nations estimate that 1.6 billion new tones of grains will need to be produced each year.

Humanity must be able to considerably increase the productivity of its farmland. Otherwise, future generations will starve to death – or all Planet Earth’s forests will have been gone.

Feeding a growing world population will require a major increase in the production of urea, the main nitrogen-based fertilizer and the building block of all other nitrogenous fertilizers, which correspond to 60 per cent of all fertilizer use.

Nitrogenous fertilizers can be only produced through burning and reforming natural gas or by gasifying coal.

However, most countries have not been producing more fertilizers because they do not have low-cost natural gas and have not had access – up to this moment – to the technology to cleanly transform its coal reserves into urea.

TransGas develops projects that employ German gasification technology to allow countries to utilize their coal reserves as feedstock to produce urea of the highest international quality standards in a clean and extremely cost-effective manner.